The Corrugated roofing sheets are a cheap way to cover a patio, shed, or greenhouse and are accessible in colors such as white, blue, and green as well as opaque colors and clear plastic. The sheets let defused light to filter through the roof while shielding you from rain. You can get corrugated roofing sheets in various lengths to decrease the number of cuts required to make the sheets implement your project, but you cannot evade cutting some sheets while the fitting process. Use the precise tools to cut the corrugated roofing material to avoid breaking the plastic sheets. We at BestDamascusKnife will give you the guide on how to cut corrugated plastic properly.

- Measure the length you want to cut, starting at one end of the corrugated plastic roofing sheet. Mark a cut line on the right and left sides and in the middle of the sheet, utilizing a felt-tipped pen.

- Line up a straightedge with the marks you obtained on the roofing sheet. Utilize your felt-tipped pen to form a straight line on the sheet.

- Add a carbide saw blade to a circular saw or multipurpose cutting tool. Cut on the straight line you painted on the roofing sheet.

- Even the cut edge, applying emery cloth.

- Redo these steps for each corrugated plastic roofing sheet you want to cut.

Everything You Will Need

-

- Tape measure

- Felt-tipped pen

- Straightedge

- Carbide saw blade

- Circular saw or multipurpose cutting tool

- Emery cloth

Tip

- Apply at least a 40-tooth carbide blade for a cleaner cut.

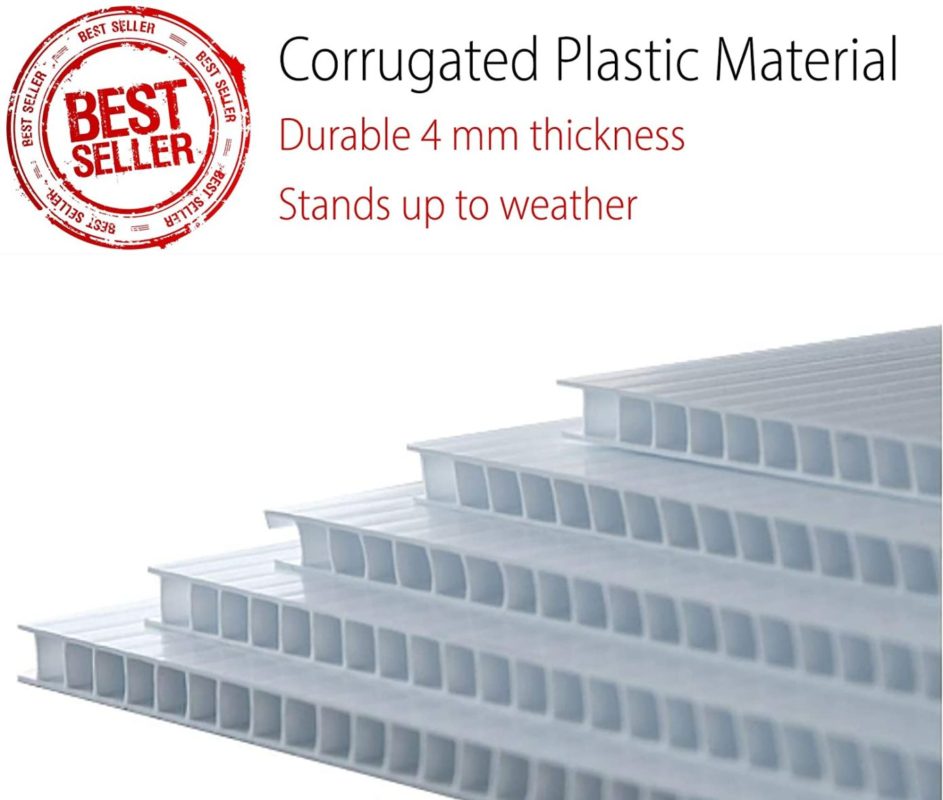

How is Corrugated Plastic Composed?

Polyethylene and polypropylene are most generally used. The polypropylene usually has additives, which can give one or more of the following characteristics to the complete product:

- Defense to chemical spills

- Neutral pH

- Balance within reasonable temperature changes

- Anti-static

- UV protection

- Fire protection

The panels are made, primarily, by the extrusion technique, where molten plastic is pumped by a die that produces the complete product its shape and thickness.

How is Corrugated Plastic Applied?

How is Corrugated Plastic Applied

The shock protection, adaptability, and versatility of twin-wall make it excellent packaging material, and, since it is recyclable, it is eco-friendly also. The twin-wall is additionally excellent for signage, such as lawn signs.

How to Cut Corrugated Plastic

Tailor your corrugated plastic cutting instruments to the particular thickness of corrugated plastic you are cutting. This material is challenging to cut and soon dulls metal blades, particularly when cutting over the grain, which is one of the benefits of utilizing Slice tools with our superintended ceramic blades to cut this material.

As explained above how to cut corrugated plastic panels, Slice makes corrugated plastic cutting instruments that instantly and simply cut by twin-wall. When cutting a full panel, support it on a flat surface applying duct tape. Evade stretching the panel and moving your cut line. Measure and mark you are wanted to cut very carefully. A straightedge is helpful while cutting.

If your twin-wall is smaller than four millimeters thick, apply either the Slice 10513 Manual Pen Cutter or the 10512 Auto-Retractable Pen Cutter. Both pen cutters utilize the identical blades. Although they will be sent using a rounded-tip blade, for security purposes, the Slice 10408 Box Cutter Blades (Pointed Tip) is insignificantly excellently suited to this material.

For twin-wall that is over four millimeters thick, the Slice 10554 Auto-Retractable Utility Knife or the 10550 Standard Utility Knife will provide you the cutting depth you want. Repeatedly, both of these utility knives utilize the identical blade, accessible in both rounded- and pointed-tip versions, although the Slice 10528 Ceramic Utility Knife Blades (Pointed Tip) is suggested.

The Corrugated Plastic Cutting Tools: The Slice Distinction

Although various cutting tools on the store will cut twin-wall, Slice tools have a different benefit. Our tools are more reliable. Applying 100 percent zirconium oxide, with more solid blades than usual ceramics, we make our safety blades with a proprietary double-angle grind, ending in a safe-to-the-touch, finger-friendly® blade edge. Auto-retractable tools provide you a combined measure of protection.

Not just are Slice blades less likely to create lacerations if the tool slips, but our blades last up to 11.2 times longer than usual metal blades. This is important when cutting materials that can dull metal blades soon because it implies that you will have fewer blade settings. Every time you renew a common blade, you risk injury.

When you join our protection blades with our handles, which are comfortable to grip and easy to hold, you can notice that the question is not very much one of how to cut corrugated plastic sheets, but rather, which Slice tools will work most helpful for you?